Click on the follow link to find out more information: https://www.langboextrusion.com/wpc-floor-extrusion-line/

Company Info

- Company Name: Zhangjiagang Langbo Machinery Co. Ltd.

- Representative: Bofeng YIN

- Product/Service: Pipe Extrusion Line , Profile Extrusion Line , Plastic Recycling Equipment , Co-Extrusion Line , Plastic Granulating Equipment , Granulating Equipment

- Capital (Million US $): 500000RMB

- Year Established: 2012

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: Above 20

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Lefeng Road 99. Leyu town, Zhangjiagang City, China

- Contact Person: Ms. Emma LIU

- Tel: +86-139-21974941

Email to this supplier

Premium Related Products

Other Products

Hot Products

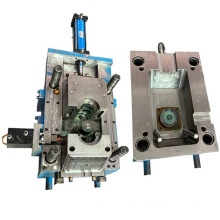

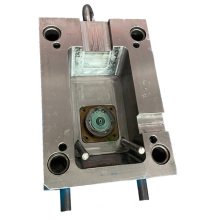

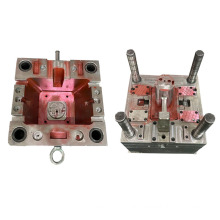

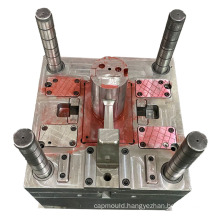

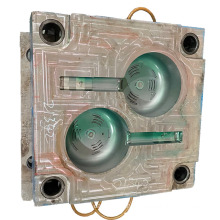

Good household washbasin mold,plastic injection molding in good deliverPlastic flower pot mould/Professional flower pot injection mouldInjection Plastic gear mould/High precision plastic gear mouldFactory Price China Auto Mold SupplierFactory Price Cap Mold Manufacturermoulds for plastic products,household plastic chair mould,auto parts plastic injection mouldWholesale China Goods Hanger MouldChina Wholesale High Quality High Quality Pet Preform MouldLatest Made In China Decent Durable Turnover Box MouldLow Cost High Quality 12 Cavity Pet Preform Blowing MouldChina Wholesale High Quality Disposable Measuring Cup MouldWholesale 2015 New Arrival Recycling Bin MouldWholesale China Goods Durable Rubbish Basket MouldHot New Products For 2015 Plastic Injection Thin Wall Containers MouldsHot China Products Wholesale Mould For Hot China Products WholesalesWholesale 2015 New Arrival Four Way Pipe Fittings Mould